Transforming Wind Turbine Maintenance: McKown Pressure Washing Drones

Introduction

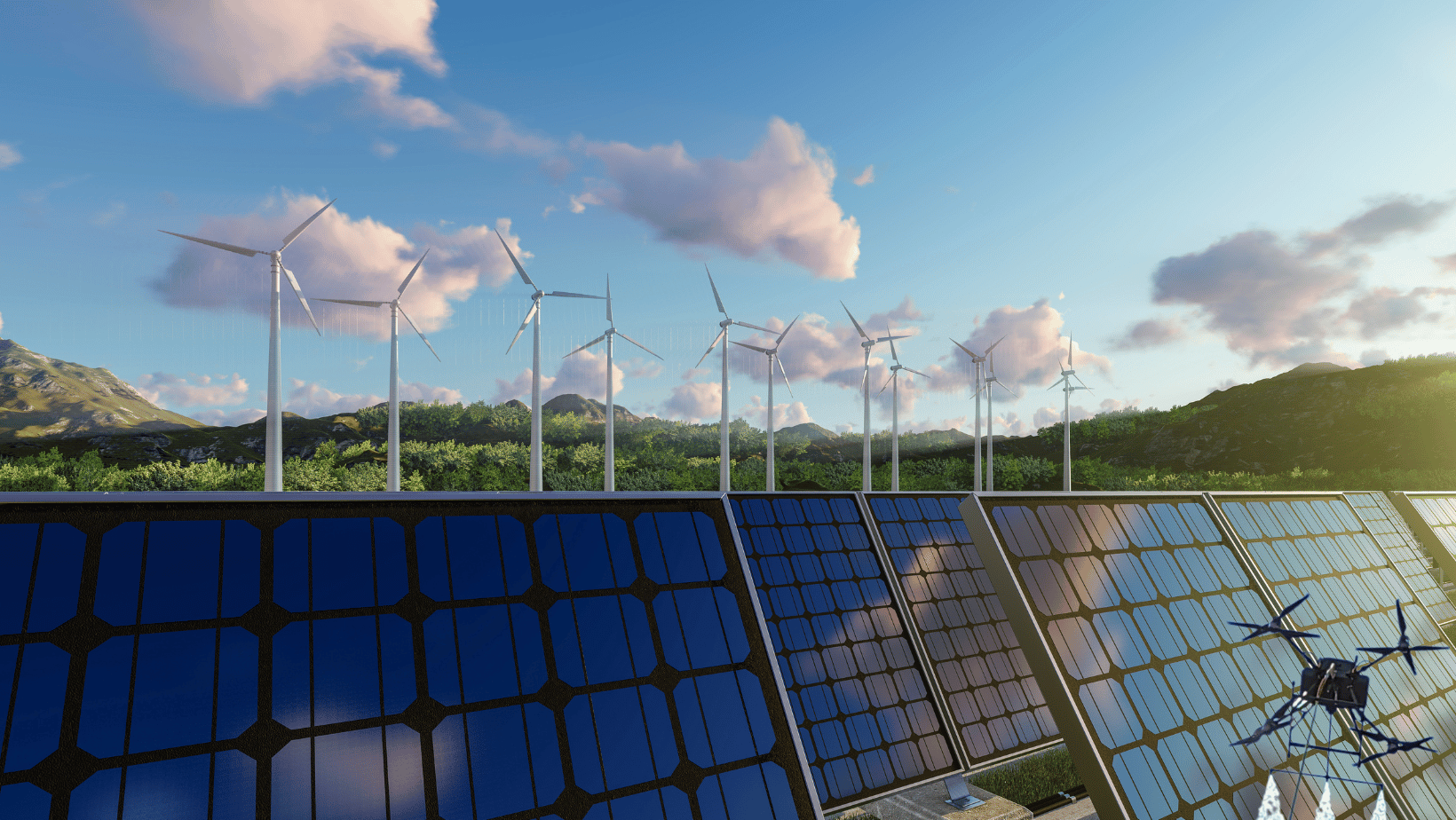

Wind turbines have become increasingly important in efforts to generate clean and renewable energy. However, these large structures require regular maintenance to ensure they function optimally and have a long lifespan.

One innovative solution that has emerged in recent years is using McKown Pressure Washing drones for cleaning wind turbines. This article will discuss the many benefits of utilizing these drones for crucial wind turbine maintenance.

The Importance Of Wind Turbine Maintenance

Maintaining wind turbines comes at a high cost and risk. Recent analysis estimates wind farm owners will spend over $40 billion on operations and maintenance in a decade. However, a study found that switching to drone-based inspections can slash operational costs by 70% and reduce revenue loss due to downtime by up to 90%.

Wind turbines are exposed to various environmental forces, including strong winds, hail, snow, lightning, rain, salt, dust, and airborne particles. Over time, these elements can accumulate on the turbine blades. This buildup can significantly decrease the turbine’s efficiency and performance, negatively impacting energy production and wind farm operators’ overall return on investment.

Traditionally, wind turbine blade cleaning required manual labor, which was time-consuming and dangerous. Technicians had to climb these massive structures, increasing the risk of accidents and injuries. Additionally, manual cleaning was not always effective in removing all contaminants, leaving wind turbines operating below their optimal performance levels.

The McKown Pressure Washing Drone Revolution For Wind Turbine Maintenance

Enter McKown Pressure Washing drones, the unsung modern wind turbine maintenance heroes. These aerial vehicles equipped with specialized pressure washing equipment have proven to be a game-changer for the industry, offering several advantages over traditional cleaning methods for preventive maintenance

Improving Wind Turbine Inspection Advancements With The Use Of Drones

Using drones in wind turbine inspection has brought several benefits over conventional inspection methods. Unlike manual inspection methods, drones eliminate the need for workers to perform dangerous tasks, reduce inspection time significantly, and avoid the need to shut down wind turbines for long periods.

Manual inspection of wind turbines is hazardous and time-consuming, often taking up to six hours and exposing inspectors to dangerous heights. However, drones are equipped with high-performance cameras and can conduct a full site assessment of wind turbine components or inspect a single turbine quickly and efficiently. They can inspect wind turbines without posing any danger to workers or requiring direct access to the turbine.

During wind turbine inspections, common defects include cracks, damage, paint peeling, corrosion, lightning traces, water penetration, and loose connections.

Take Aways…

Wind-generated electricity has increased by nearly 17% in 2021, which is a growth rate of 55% higher than the previous year. This trend is expected to continue and even accelerate, making the introduction of McKown Pressure Washing drones particularly timely as more wind turbines will require maintenance.

McKown Pressure Washing drones are valuable for maintaining wind turbines, offering improved safety, efficiency, and accuracy. As renewable energy continues to expand, these drones are set to play an even more significant role in keeping turbines clean.

Thanks to advancements in drone technology and increased industry usage, the future of wind turbine maintenance looks brighter and more sustainable than ever before. McKown Pressure Washing drones are helping ensure that wind turbines operate at their maximum capacity, paving the way for a cleaner and greener future as the world aims to meet its clean energy goals.

To obtain further information about our drone pressure washing services, kindly contact us during our office hours from Monday to Friday between 8:00 a.m. and 4:00 p.m. Eastern Standard Time, (except on major holidays), at (757) 224-0879

You may also email us for any general inquiries or questions at info@mckownpressurewash.com